Services

Services provided by Unik Engineering System

- Unik Engineering System begins by conducting a comprehensive analysis of your project’s specific requirements and objectives.

- Our multidisciplinary team of engineers, designers, and project managers collaborates closely with you to create a detailed roadmap.

- Our designs prioritize not only functionality, efficiency, and cost-effectiveness but also scalability and adaptability to evolving project needs.

- We leverage cutting-edge design software and tools to ensure precision and innovation in every aspect of your project.

- Our advanced laser cutting machines are equipped with the latest technology, including computer-aided design (CAD) integration, to achieve unparalleled precision.

- We excel in handling various materials, including metals, plastics, and composites.

- Complex shapes, intricate patterns, and fine details are executed with exceptional accuracy and speed.

- Our laser cutting services are trusted in industries such as aerospace, automotive, and architectural design for their reliability and precision.

- Machines used – Trump India – TRULASER 3030, TRULASER 1060

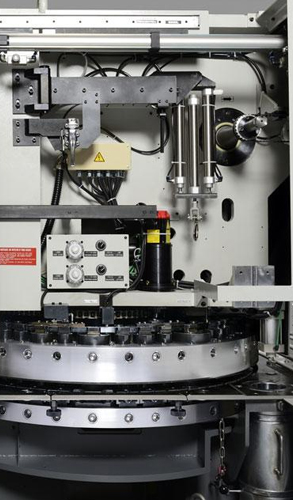

- Unik Engineering System’s turret punching machines are equipped with multiple tool stations, allowing for a wide range of punching options.

- We offer fast and precise punching services for materials of various thicknesses.

- Our engineers can assist in optimizing hole patterns and designs for maximum efficiency and structural integrity.

- The versatility of our turret punching capabilities makes us a go-to choice for projects requiring consistency and high-quality hole patterns.

- Our CNC metal bending services ensure that your metal components meet exact specifications.

- We work with materials such as steel, aluminum, and stainless steel, providing flexibility in material selection.

- Precision CNC control guarantees uniform bends, minimizing errors and rework.

- Custom tooling options enable us to accommodate complex geometries and angles.

- Machines used – Hindustan and GMT

- Unik Engineering System’s expertise in pipe cutting and bending extends to a wide variety of industries.

- We specialize in handling diverse pipe materials, including steel, copper, and PVC.

- Custom configurations, beveling, and end forming are executed with precision.

- Our attention to detail ensures that pipes fit seamlessly into your systems, optimizing performance and minimizing leaks.

- Our power press punch machines are capable of handling high-volume and heavy-duty punching requirements.

- They are equipped with advanced automation features for efficiency and consistency.

- This service is essential for projects where reliability and precision in hole creation are critical.

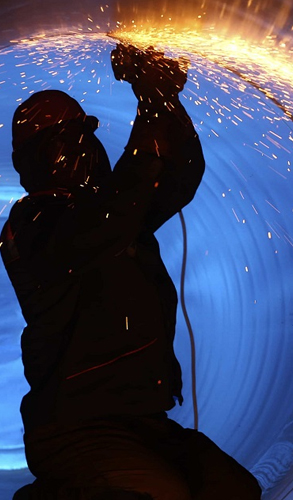

Unik Engineering System’s welding and fabrication capabilities cover a wide spectrum:

- Arc Welding: Ideal for structural and heavy-duty applications, providing robust and long-lasting welds.

- MIG Welding: Versatile for various metals and thicknesses, offering efficiency and strong welds.

- TIG Welding: Ensures precise and clean welds, suitable for intricate work and materials like aluminum.

- Spot Welding: Perfect for joining thin materials, commonly used in automotive and electronics manufacturing.

- Laser Welding: Delivers high precision and minimal heat-affected zones, ideal for delicate or high-precision components.

- Unik Engineering System’s embossing and engraving services add aesthetic and functional value to your components.

- We offer a wide range of customization options, including logos, part numbers, and decorative elements.

- Our precision equipment ensures that embossed or engraved elements meet your branding or labeling needs accurately.

Our painting, powder coating, and galvanization services protect your components from corrosion and enhance their appearance:

- Painting: Offers a variety of color options for customization while providing protection against environmental factors.

- Powder Coating: Ensures a durable and attractive finish with resistance to chipping and scratching.

- Galvanization: Provides long-lasting corrosion resistance for outdoor and harsh environments.

- 7 stage of chemical cleaning

- Unik Engineering System’s commitment to your project extends to installation and erection services.

- Our experienced team coordinates all aspects of on-site assembly, ensuring components are correctly positioned and integrated.

- We prioritize safety, efficiency, and adherence to project timelines, providing a seamless transition from manufacturing to installation.

Unik Engineering System combines cutting-edge technology,

A highly skilled team of professionals, and an unwavering commitment to excellence to deliver top-tier solutions across diverse industries.

Expertise: Our Expertise is Your Advantage

At Unik Engineering Systems, we take pride in our extensive experience and a highly skilled team of professionals. Our journey through the years in the sheet metal fabrication industry has honed our skills to perfection. When you choose us, you’re selecting a partner with a proven track record in delivering top-quality results. We bring this wealth of expertise to every project, ensuring that you receive solutions that are not only precise but also optimized for your specific needs.

Innovation and Precision: Where Quality Meets Precision

Innovation and precision are at the core of what we do. We are continually pushing the boundaries of sheet metal fabrication techniques and investing in cutting-edge technology. This commitment to innovation guarantees that your projects benefit from the latest advancements in the industry. Our precision ensures that every component and assembly we produce meets the highest quality standards, ensuring reliability, durability, and performance.

Industry Diversity: Tailored Solutions for Every Sector

Unik Engineering Systems understands that each industry has its unique set of challenges and requirements. Whether you’re in the construction, automotive, electronics, or engineering sector, we’ve got you covered. We’ve successfully served a wide range of professional industries, and this diverse experience equips us with the knowledge to provide tailored solutions that align perfectly with your industry’s demands. Our versatility allows us to adapt to your industry-specific needs, delivering results that stand out.

Seamless Integration: Making Your Components Fit Perfectly

Integration assemblies are complex and require meticulous attention to detail. At Unik Engineering Systems, we specialize in creating components and assemblies that seamlessly fit into your larger systems. Whether it’s electrical enclosures, automotive components, or custom metal structures, we ensure that our products integrate flawlessly, minimizing downtime and maximizing efficiency for your operations.

Customer Focus: Your Vision, Our Priority

We understand that your success is our success. That’s why we are dedicated to putting our customers first. When you choose Unik Engineering Systems, you’re choosing a partner that works closely with you from the initial concept to project completion. We take the time to understand your objectives and vision, ensuring that our solutions align perfectly with your goals. Your satisfaction is our ultimate priority, and we are always ready to address your inquiries and provide solutions that meet and exceed your expectations.